Sandwich Mountings

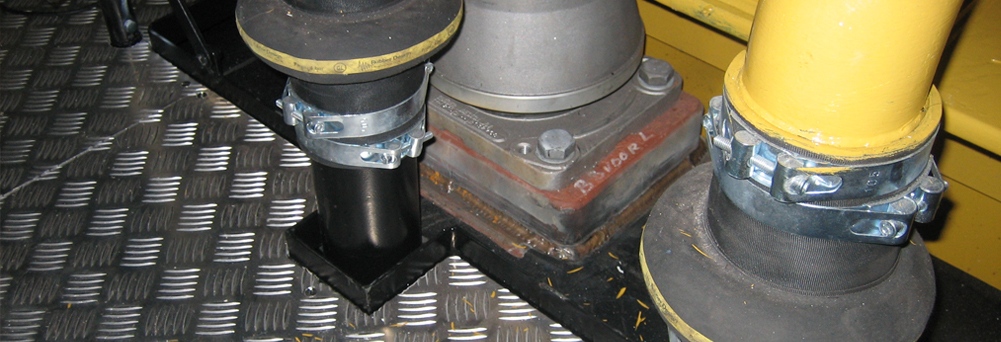

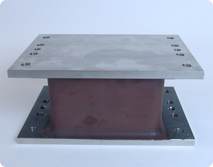

Available with or without interleaf, the sandwich mountings – VRD 34/35 type mountings are produced in a range of rubber mixes (M45, MN50 and MN55) and sizes, close to stiffness tolerances, for use as main and auxiliary engine mountings. This type of mounting can also be used in earthquake areas. In that case, additional calculations are required. All mountings are individually tested and selected on stiffness.

Sandwich mountings, horizontally mounted for stationary applications

For land-based / stationary applications, sandwich mountings can be placed horizontally underneath the generator set, in order to provide a resiliently mounted system. Selection of the amount and rubber hardness of the sandwich mountings, as well as the position of the sandwich mountings, is done based on the weight of the installation, and the disturbing frequencies that have to be isolated.

Sandwich mountings are perfectly suited for these installations based on their high permanent workload capacity, and their excellent isolating capabilities, combined with a relatively low price. Besides, installation of these mountings is very easy, both on initial assembly as well as upon replacement of the sandwich mountings.

V-system

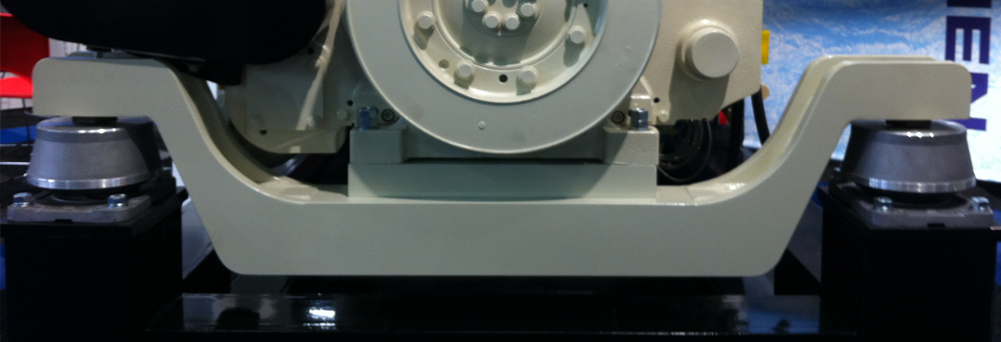

A combination of sandwich mountings arranged in a ‘V’ system allows considerable flexibility to the designer. The important natural frequencies can be positioned into the excitation free frequency bands and in addition seaway and torque movements are relatively low at the coupling position. A ‘V’ system applies to the installation of a main engine and particularly to a medium speed engine. With high speed engines the design is in most cases much simpler than that of the medium speed engine.

The acoustic properties of the sandwich mountings are excellent. The result of the measured structure borne vibration and noise transmission are available. In both the vertical and horizontal direction, the transfer functions show in the low frequency range a decrease of 12 dB/octave which can be compared with an ‘ideal mass less spring characteristic’. We will be pleased to undertake all suspension design calculation and advise on mounting type, quantity, position and rubber mix to ensure a ‘faultless’ flexible mounted installation. Before we can commence the design of a ‘V’ system, detailed information is required.

Contact us:

Rubber Design B.V.

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

Tel: +31 (0)78-6778778

Postal address:

P.O. Box 15

2995 ZG Heerjansdam

The Netherlands

info@rubberdesign.nl

www.rubberdesign.nl

Products & Services

Latest News

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32 Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46 NMT important export partner for Rubber Design16 October 2023 - 20:06

NMT important export partner for Rubber Design16 October 2023 - 20:06