Engine & Gearbox Mountings

Rubber Design’s conical and sandwich mountings find their way to ships, trains and installations in earthquake areas.

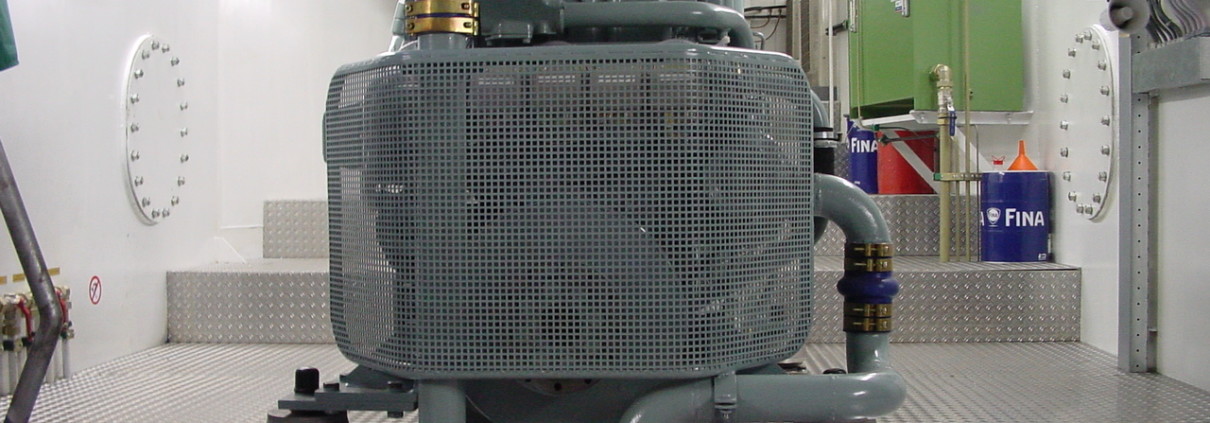

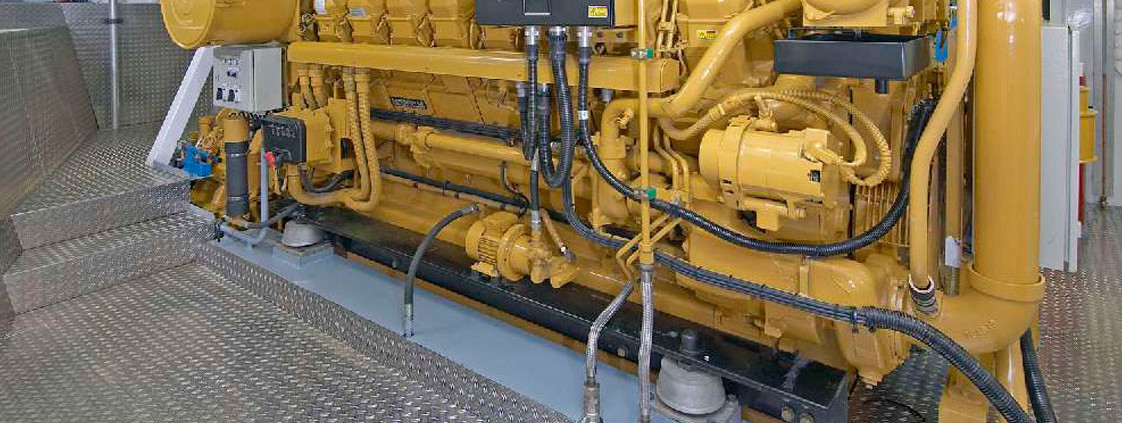

Although originally designed for main engine, auxiliary engine and generator installations, the mountings are particularly versatile and can equally be used for exhaust gas boilers and silencers.They are well accepted in the market and used by many engine manufacturers as standard.

The conical mountings and our calculation method have been approved on many applications by the major international classification societies. Serial numbers of all supplies are registered in one single database. Therefore we can supply the genuine parts in case a client needs spare parts.

The range of conical mountings is designed especially with medium speed engines in mind. The conical design provides high deflection and load capacity combined with long service life. Available with or without interleaf, the sandwich mountings are produced in a range of rubber mixes and sizes, to meet stiffness tolerances. This type of mounting can also be used in earthquake areas. Selection of the rubber hardness and the position of the sandwich mountings is done based on the weight of the installation and the disturbing frequencies that have to be isolated. All mountings are individually tested and selected on stiffness.

Solutions that perform in all conditions

We design, produce, test and deliver custom made solutions. We join the building process in a very early stage of the development of the vessel, which enables us to come up with solutions that perform in all the conditions a client may think of.

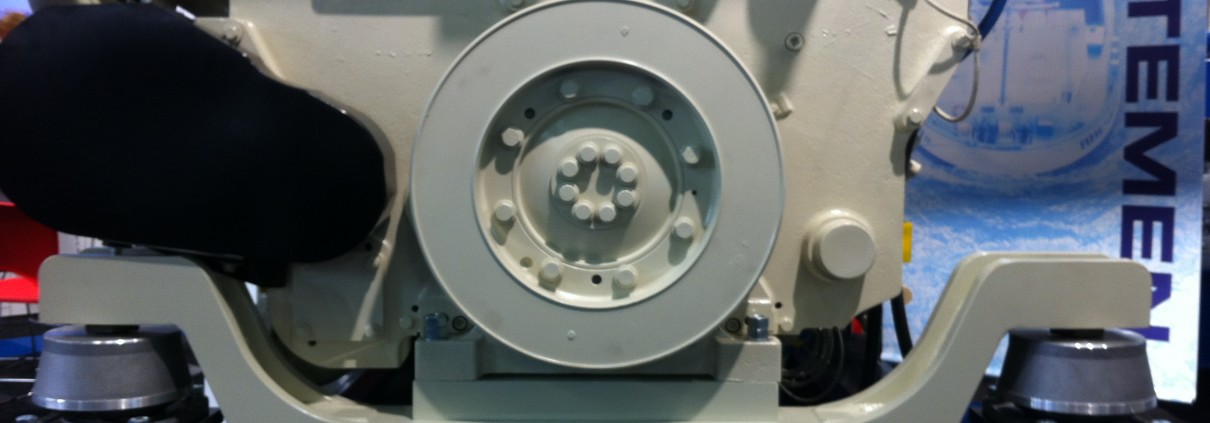

The range of propulsion equipment consists of TT (Thrust Torque) mountings, gearbox mountings, marine and flexible couplings and thrust bearings. Rubber Design can perform a complete dynamic analysis of a vessel’s propulsion system in order to select the correct coupling and engine mounts for each application. CAD drawings (2D/3D) of the thrust blocks and marine couplings are available in different formats and can be easily imported into the CAD drawing of the complete propeller shaft installation. All thrust blocks and marine couplings can be delivered with the required classification approval.

Contact us:

Rubber Design B.V.

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

Tel: +31 (0)78-6778778

Postal address:

P.O. Box 15

2995 ZG Heerjansdam

The Netherlands

info@rubberdesign.nl

www.rubberdesign.nl

Products & Services

Latest News

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46 NMT important export partner for Rubber Design16 October 2023 - 20:06

NMT important export partner for Rubber Design16 October 2023 - 20:06 Damen and Rubber Design working together on the combat support ship16 October 2023 - 20:03

Damen and Rubber Design working together on the combat support ship16 October 2023 - 20:03