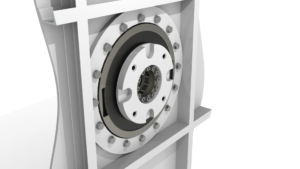

Compact Thrust block

COMPACT THRUST BLOCK

The Rubber Design Compact Thrust Block CTB is an addition to the existing thrust bearing range. The CTB has been developed for compact dimensions in combination with our SMART-LINK coupling.

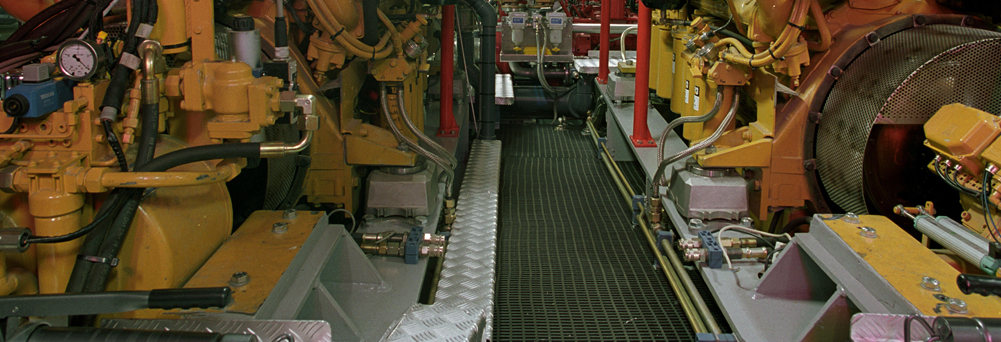

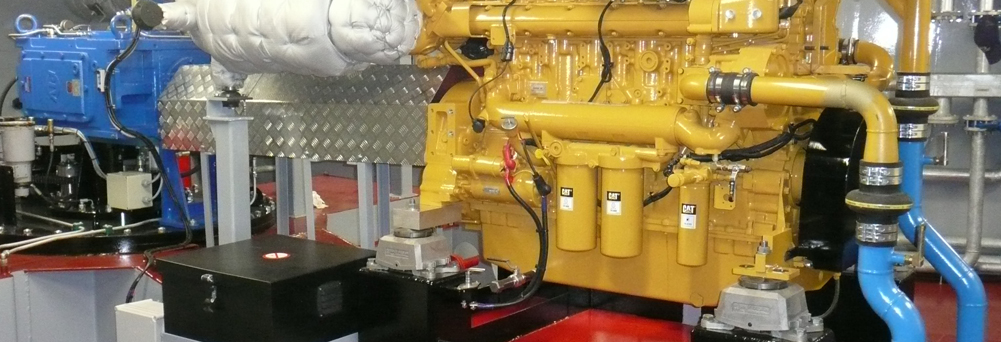

A separate thrust block allows for an optimum flexible mounting system of engine and gearbox (close coupled) leading to the best results for noise and vibration isolation of the propulsion system.

SPECIFICATION

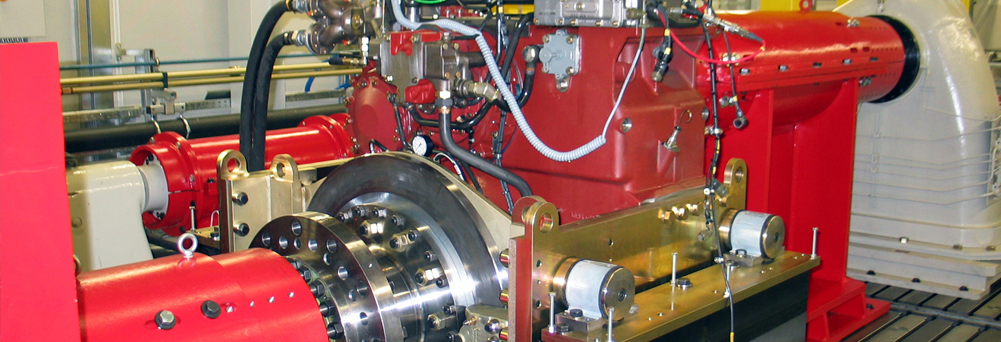

Our Compact Thrust bearing Block is based on a spherical design. This gives the thrust bearing block the opportunity to adjust if there is any angular misalignment. This misalignment can occur during operation of the propeller shaft line. Also by alignment on board the ship this spherical design allows some more misalignment between shaft and housing. The design allows till an adjustment angle of 5°.

The thrust block can take radial and axial forces. The axial forces are for the fwd and reverse

thrust loads. The radial forces to support the shaft weights. The bearing life time of our thrust bearing block is of very high standards. The best quality bearings with a bearing life higher than the minimum requirements from classification society. Bearing life calculation is based on worst case scenario’s.

The thrust bearing is grease lubricated and therefore low maintenance required. This type of thrust bearing block could be mounted on the propeller shaft instead of using its own thrust shaft. The thrust bearing block only needs a cylindrical shaft. Adjustment to current shaft diameters can be done with a split spacer bush. Another advantage of the compact thrust bearing is that it could be integrated in existing situations. This could be very interesting for ship owners who want to update their shaft installation to newer standards during refit operations or when engine is be replaced. By adding the thrust bearing block in the propeller shaft installation great benefits will occur by low noise en vibration levels onboard due to updated resilient mounting systems.

Contact us:

Rubber Design B.V.

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

Tel: +31 (0)78-6778778

Postal address:

P.O. Box 15

2995 ZG Heerjansdam

The Netherlands

info@rubberdesign.nl

www.rubberdesign.nl

Products & Services

Latest News

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46 NMT important export partner for Rubber Design16 October 2023 - 20:06

NMT important export partner for Rubber Design16 October 2023 - 20:06 Damen and Rubber Design working together on the combat support ship16 October 2023 - 20:03

Damen and Rubber Design working together on the combat support ship16 October 2023 - 20:03