Marine Couplings

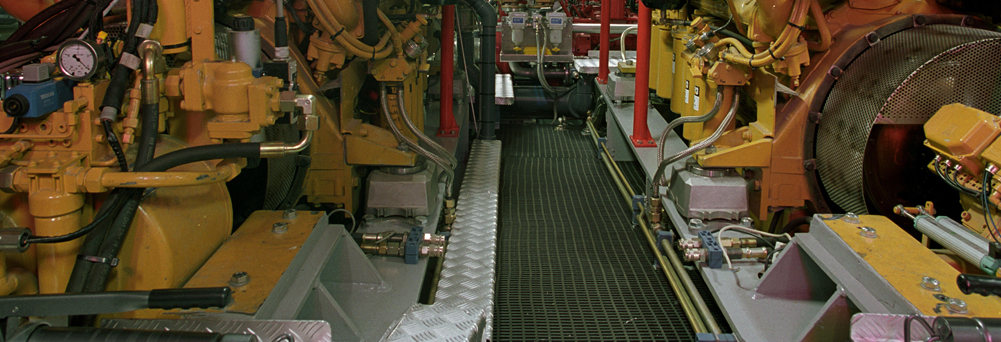

Rubber Design has the in-house skills and expertise necessary to perform a complete dynamic analysis of a vessels propulsion system in order to select the correct coupling and engine mountings for each application. This ensures that the coupling and engine mountings work together in perfect harmony.

SMART-LINK flexible coupling

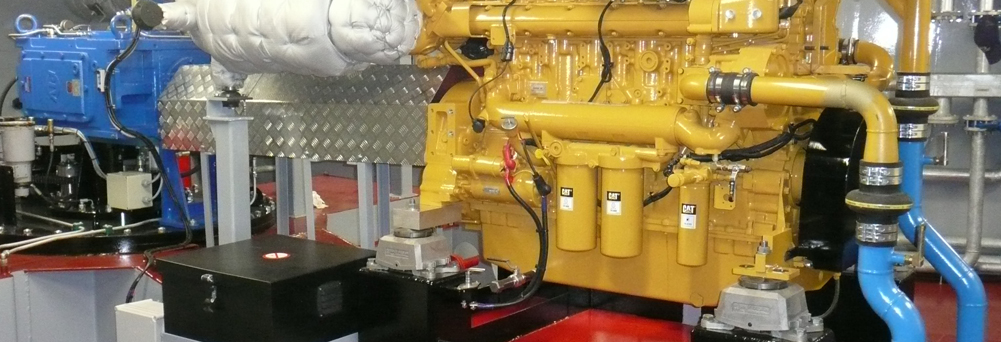

The Rubber Design SMART-LINK Flexible Coupling (Stable Movement, Axial, Radial, Torsional) is a newly developed coupling system that combines rubber link elements with synthetic cord inlays. The high degree of allowable displacements and associated low stiffness enhances the effectiveness of the SMART-LINK flexible coupling when applied with soft mounted flexible systems.

Although specifically designed as a marine propulsion secondary coupling, its use is not limited to the main propulsion only.

Other well-suited applications are waterjets, thrusters, alternators, electric motors and (hydraulic) pumps.

The single and dubble row torque-link design has an optimal torque capacity versus the smallest possible outside diameter.

The SMART design of the coupling results in the smallest possible built-in length with maximum flexibility.

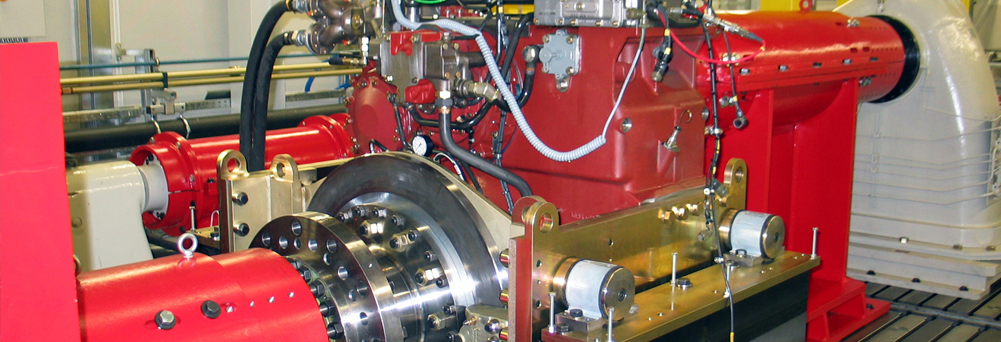

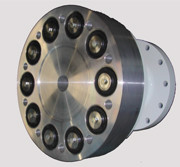

Marine Couplings type ERD

Pre-compressed rubber blocks form the basis of all ERD coupling designs. Natural rubber of 55˚-60˚Sh.A hardness is the standard material, but alternative mixes are available and neoprene blocks are used where additional damping is required. The blocks accommodate movement in all directions, making ERD couplings exceptionally tolerant of relative propeller shaft displacements in combination with flexible mounted propulsion engine and providing controlled torsional vibration excitation.

Advantages of the ERD marine coupling:

– Reduction of torque fluctuations

– Damping of torsional vibrations

– Reduction of resonance symptoms

– Compensating of radial, axial and angular shaft displacements including thrust/pressure absorption

– Isolation of vibration and noise transmission

Exclusive partner supplier for marine coupling components for Rubber Design

Süddeutsche Gelenkscheibenfabrik GmbH&Co. KG

www.sgf.com

industry@sgf.com

+49 8638 605-588

Exclusive worldwide

sales partner for marine

propulsion equipment of SGF

Contact us:

Rubber Design B.V.

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

Tel: +31 (0)78-6778778

Postal address:

P.O. Box 15

2995 ZG Heerjansdam

The Netherlands

info@rubberdesign.nl

www.rubberdesign.nl

Products & Services

Latest News

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32 Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46 NMT important export partner for Rubber Design16 October 2023 - 20:06

NMT important export partner for Rubber Design16 October 2023 - 20:06