Rubber Shock Mountings

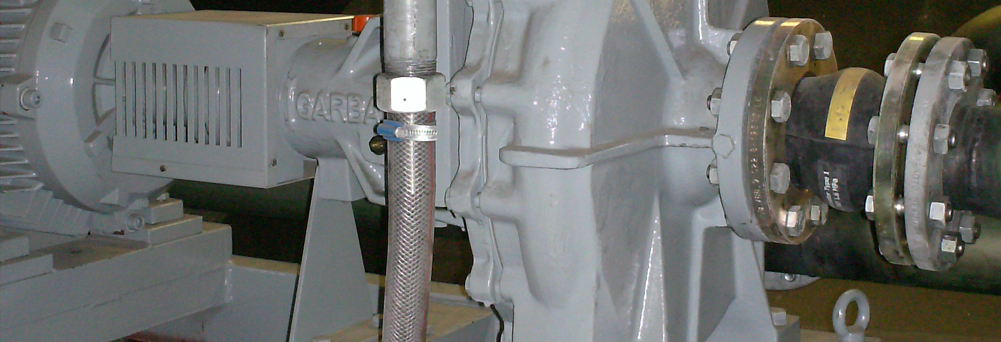

Rubber Design developed the RDS shock mountings mainly for marine applications. These type of mountings can stand a linear shock deflection of 80 mm. The RDS shock mountings meet the requirements of all international shock specifications such as BV 043, BV 044, MIL-STD901D, STANAG 4142 and M.O.D. BR 3021.

The RDS shock mountings are particularly suitable for marine applications such as propulsion engines, diesel generator sets and auxiliary equipment where attenuation of low frequencies is required.

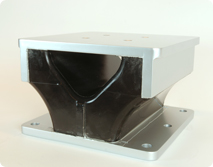

RDS – EPM Mountings

In addition to the existing RDS mounting range, the new EPM mountings (type RDS-C165/95, RDS-C165/126 & RDSC250/154) provide the ideal solution for the protection of small equipment (up to 10 kN per mounting) like water makers, pump sets, generator sets and hydro-packs, while also isolating the vibrations.

The unique Equipment Protection Mounting (EPM) design enables the mounting to absorb large shock displacements while ensuring an excellent vibration isolation. The RDS EPM has a linear stiffness over a wide load range varying from compression to extension which is necessary to maintain the optimum isolation properties. This new mounting range is the ideal solution for small rotary equipment which need a combination of vibration and shock isolation. The maximum deflection of the mounting as result of shock impact is as large as up to 50 mm in all directions. Due to the conical round shape the RDS EPM’s have identical stiffness characteristics in longitudinal and transverse direction.

The mountings are individually tested and marked with date of production and identification numbers. The new RDS EPM-mountings meet all requirements of international shock specifications, such as BV-043, BV-044, MIL-STD-901, STANAG, MOD etc.

Sandwich Mountings for shock

Available with or without interleaf, the sandwich mountings – VRD 34/35 type mountings are produced in a range of rubber mixes (M45, MN50 and MN55) and sizes, close to stiffness tolerances, for use as main and auxiliary engine mountings. This type of mounting can also be used in earthquake area’s. In that case, additional calculations are required. All mountings are individually tested and selected on stiffness.

Contact us:

Rubber Design B.V.

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

Tel: +31 (0)78-6778778

Postal address:

P.O. Box 15

2995 ZG Heerjansdam

The Netherlands

info@rubberdesign.nl

www.rubberdesign.nl

Products & Services

Latest News

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32 Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46 NMT important export partner for Rubber Design16 October 2023 - 20:06

NMT important export partner for Rubber Design16 October 2023 - 20:06