Engineering Services

General design & engineering capabilities

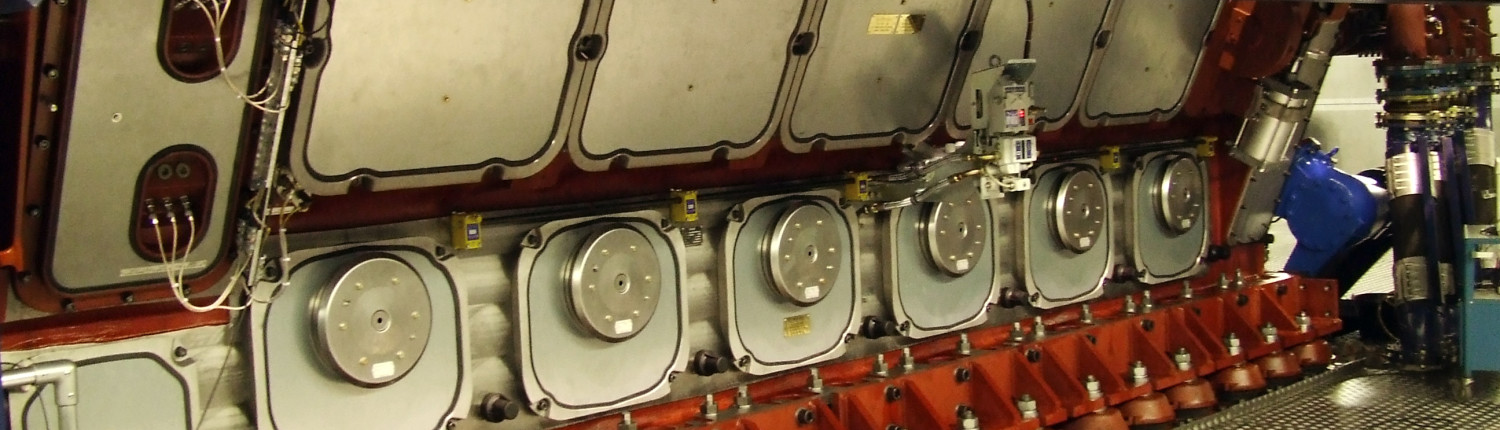

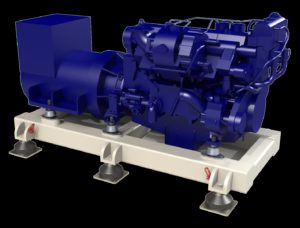

Based on Rubber Design’s vast experience with resilient mounting systems and vibration isolation technology, we have developed fail-safe engineering and calculation practices for the design, engineering and development of all vital parts within a resilient mounting system. Working with over 30 years of experience, Rubber Design is an excellent partner to design a proper engine bracket, subframe, foundation, or even a complete double resilient mounting system.

Resilient mounting systems

For initial selection of anti-vibration mountings the characteristics table in our documentation is ideal, however, it is advis-able to seek expert advise before finalizing an installation design. In case of double resilient mounting systems, Rubber Design has the experience and tools to support you with these calculations.

Results will be provided in a complete report with conclusions on best mounting option, natural frequencies with isolation performance of the set, displacement of connections, structure born noise isolation, etc. etc.

Rubber Design is eager to serve you as a turn-key vibration technology partner.

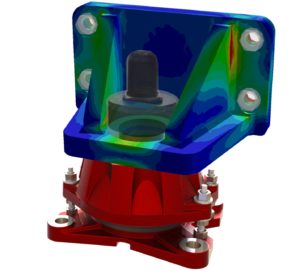

Static and dynamic analysis of structures

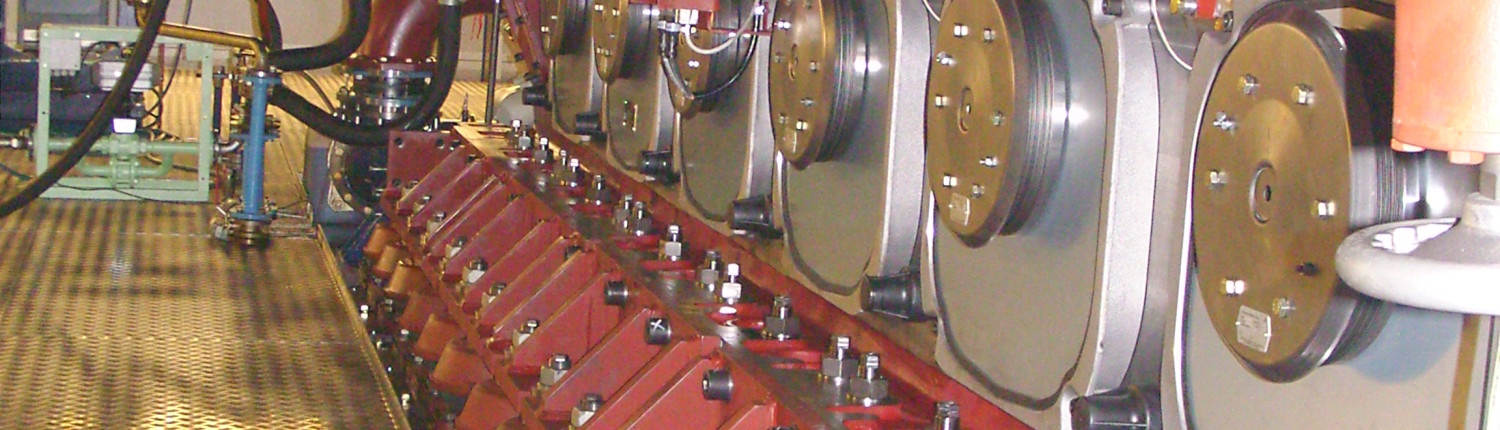

For the best isolation performance of a resilient mounting system, it is very important that the dynamic stiffness/mobility of the structure above and below the anti-vibration mount is adequate for the selected mounting. To prevent bad isolation performance it is very important to check the static and dynamic characteristics of the structure in the design phase.

Rubber Design has the experience and tools to design the best possible engine bracket, subframe and/or foundation for the selected anti-vibration mount, so that high-level isolation of structure borne noise can be realized.By optimizing the design for strength, natural frequencies, mobility and ease of production, we can supply our customers with a cost-efficient, tailor-made, proven turn-key solution.

Results

When looking for a fail-safe solution, which will work satisfactory in the field for many years with predictable and high-level isolation performance, Rubber Design is your partner! This is secured by the approval of our design-, engineering- and calculation methods by many renown engine manufacturers and classification societies.

Contact us:

Rubber Design B.V.

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

Tel: +31 (0)78-6778778

Postal address:

P.O. Box 15

2995 ZG Heerjansdam

The Netherlands

info@rubberdesign.nl

www.rubberdesign.nl

Products & Services

Latest News

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32 Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46 NMT important export partner for Rubber Design16 October 2023 - 20:06

NMT important export partner for Rubber Design16 October 2023 - 20:06