Measurement & Consultancy

Noise and vibration measurements

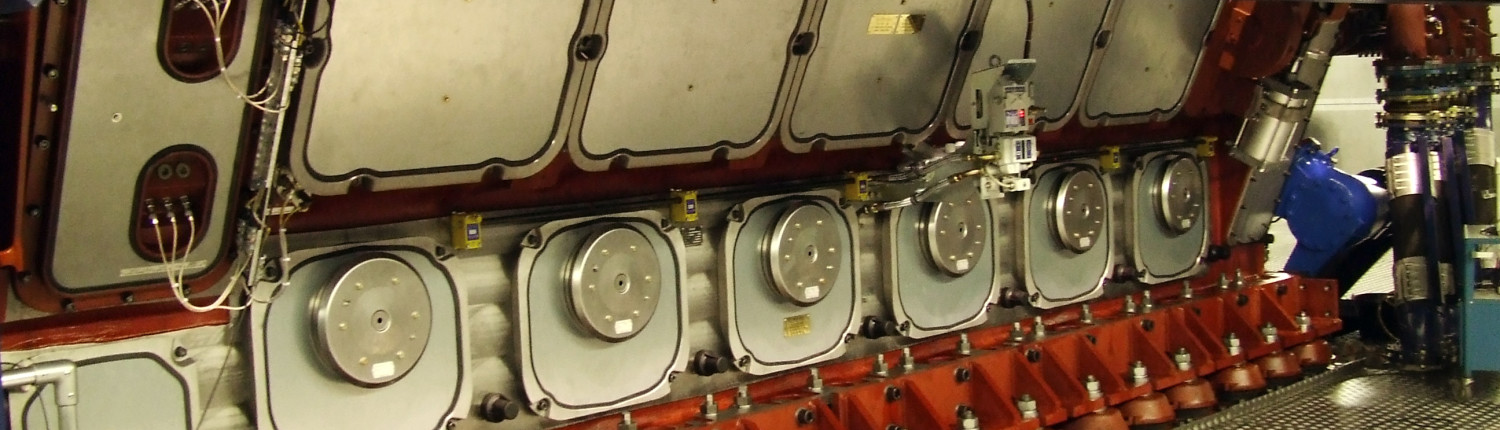

To confirm if vibration levels of equipment (rigid or flexible) are within the limits of equipment supplier or ISO stan-dard, Rubber Design can perform vibration measurements with high quality measurement devices. To prevent high noise levels the structure borne noise level below the anti-vibration mounts of a resilient mounted system should be below specified limits. Rubber Design can measure noise and structure borne noise levels according ISO standards to confirm if the specified noise and vibration levels are realized.

Structural vibration measurements

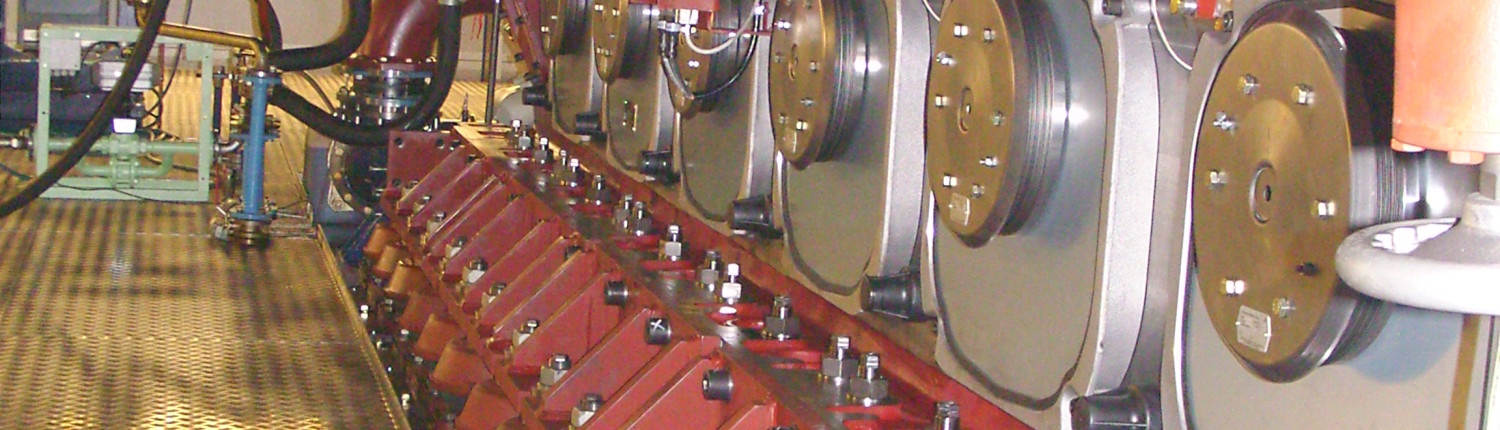

To detect noise and vibration problems in an early stage of the build process, Rubber Design has the experience and equipment to measure the dynamic response of structures.

By the use of an impact hammer or electrodynamic shaker, the mobility of a structure can be measured to check if the value is adequate to guarantee a good isolation performance of the anti-vibrations mounts. If values are not adequate we will advice you which modifications are necessary to realize an acceptable mobility value for the structure.

To prevent resonance of the structure due to excitations, Rubber Design has the equipment and knowledge to measure the dynamic response of the structure. With the use of a large impact hammer and roving sensor technique the re-sponse of the structure is measured. Natural frequencies and mode shapes are determined, conclusions regarding the design of the structure can be made and if necessary, Rubber Design can advise you how to improve the dynamic re-sponse of the structure.

Trouble-shooting

When you have specific noise or vibration problems, Rubber Design can help you solving these problems by performing measurements to identify the cause of the problem. We will not only give you a report with the cause of the problem, but will advise you how to solve this issue quickly ! To determine the cause of the vibration problem 3D animations can be made to observe order-related Operating Deflection Shapes from running machinery, resonant vibration and mode shapes from real structures.

Capabilities & inquiries

More detailed descriptions of our capabilities and quotation for engineering work can be provided upon request.

Please contact us with a description of the work to be performed and we will serve you with a detailed quotation.

Contact us:

Rubber Design B.V.

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

Tel: +31 (0)78-6778778

Postal address:

P.O. Box 15

2995 ZG Heerjansdam

The Netherlands

info@rubberdesign.nl

www.rubberdesign.nl

Products & Services

Latest News

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32 Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46 NMT important export partner for Rubber Design16 October 2023 - 20:06

NMT important export partner for Rubber Design16 October 2023 - 20:06