Production

Due to the unique alliance with the specialized production and engineering company Biezepol, Rubber Design is able to offer the customer a total product. In the river-based premises both companies have all disciplines under one roof. Design, testing and production through to assembly and logistics all take place in Heerjansdam, which contributes to an efficient running of all the processes.

Especially in the case of more demanding products, tailormade solutions and smaller production runs we strongly believe in the combination between machine, product and employee. Therefore we invest heavily in the skills of our employees and the possibilities and capacity of our machinery. Some products though, need to be produced in ever increasing numbers. That’s why we also invest in automation to let computerized robots take care of parts of the production process.

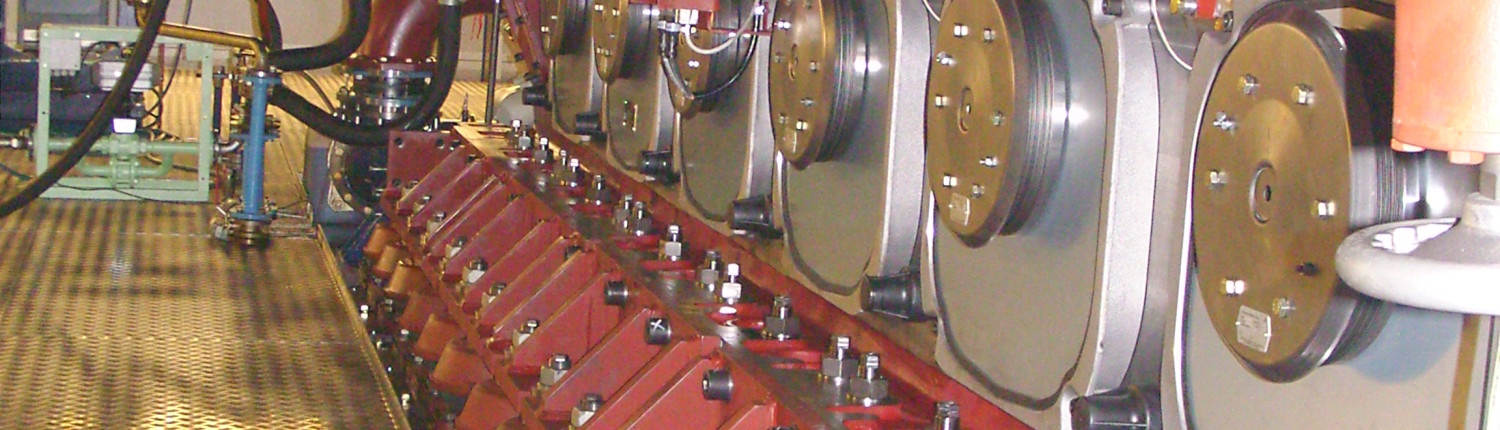

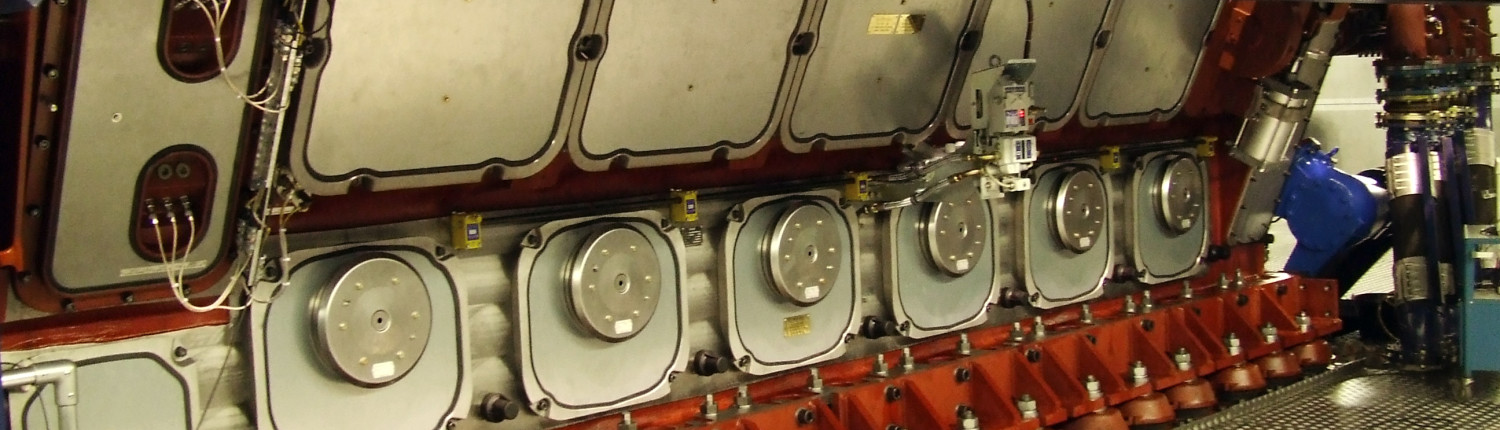

Assembly

In-house assembly helps us control the customer’s specific demands as it comes to quality. Whether products are manufactured in large numbers, or tailor-made. Some products are so specific, that the assembly requires very special needs. The propeller shaft installations for example are only custom made. We design, prepare and test them within our premises. Final assembly and installation take place on-site all over the world.

The products we make consist of different components and rubber compounds. In-house assembly helps us to make sure that all products are being manufactured exactly as they were designed on the drawing table. It also increases our flexibility and our capacity to provide tailormade solutions.

We work with various assembly lines, which are partly automated. But an important part of the process is still being done manually, because nothing replaces the accurateness and knowhow of our employees. This goes for the administrative process as well. Rubber Design can take care of the issuing of all the relevant certificates, licenses and permits.

” Rubber Design pays attention to the tiniest little detail. That’s the reason why we do the assembly ourselves. To make sure that all our products are delivered exactly according the customer’s demands .”

Contact us:

Rubber Design B.V.

Industrieweg 21

2995 BE Heerjansdam

The Netherlands

Tel: +31 (0)78-6778778

Postal address:

P.O. Box 15

2995 ZG Heerjansdam

The Netherlands

info@rubberdesign.nl

www.rubberdesign.nl

Products & Services

Latest News

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32

New Partner Announcement – ANV INNOVATION LTD. (Turkey)14 August 2025 - 16:32 Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46

Embrace: The Future of Silent, Efficient Superyacht Propulsion31 October 2024 - 16:46 NMT important export partner for Rubber Design16 October 2023 - 20:06

NMT important export partner for Rubber Design16 October 2023 - 20:06